Driving Innovation in Urban Sanitation: The Role of 3D Printing in Manufacturing State-of-the-Art Street Cleaning Trucks

In the rapidly evolving landscape of urban infrastructure and environmental sustainability, the intersection of 3D printing technology and public service equipment is creating new avenues for efficiency, customization, and technological advancement. Among the numerous applications of 3D printing, one of the most impactful is its role in revolutionizing the design, production, and maintenance of street cleaning trucks. This article delves into how forward-thinking businesses like ceksansweepers.com are leveraging these innovations to set new industry standards, improve operational efficiency, and promote sustainable urban living.

The Evolution of Street Cleaning Trucks: From Traditional to Technologically Advanced

Historically, street cleaning trucks have been essential components of urban infrastructure, tasked with maintaining cleanliness and public health. Early models relied heavily on manual assembly, conventional manufacturing methods, and limited customization options. Over time, the push for enhanced performance, environmental sustainability, and cost efficiency has driven the industry toward more sophisticated solutions.

Recent advancements now integrate smart technology, eco-friendly materials, and innovative manufacturing processes, with 3D printing standing out as a transformative force in the development of next-generation street cleaning trucks. These innovations are shaping a future where urban sanitation becomes more adaptable, efficient, and sustainable.

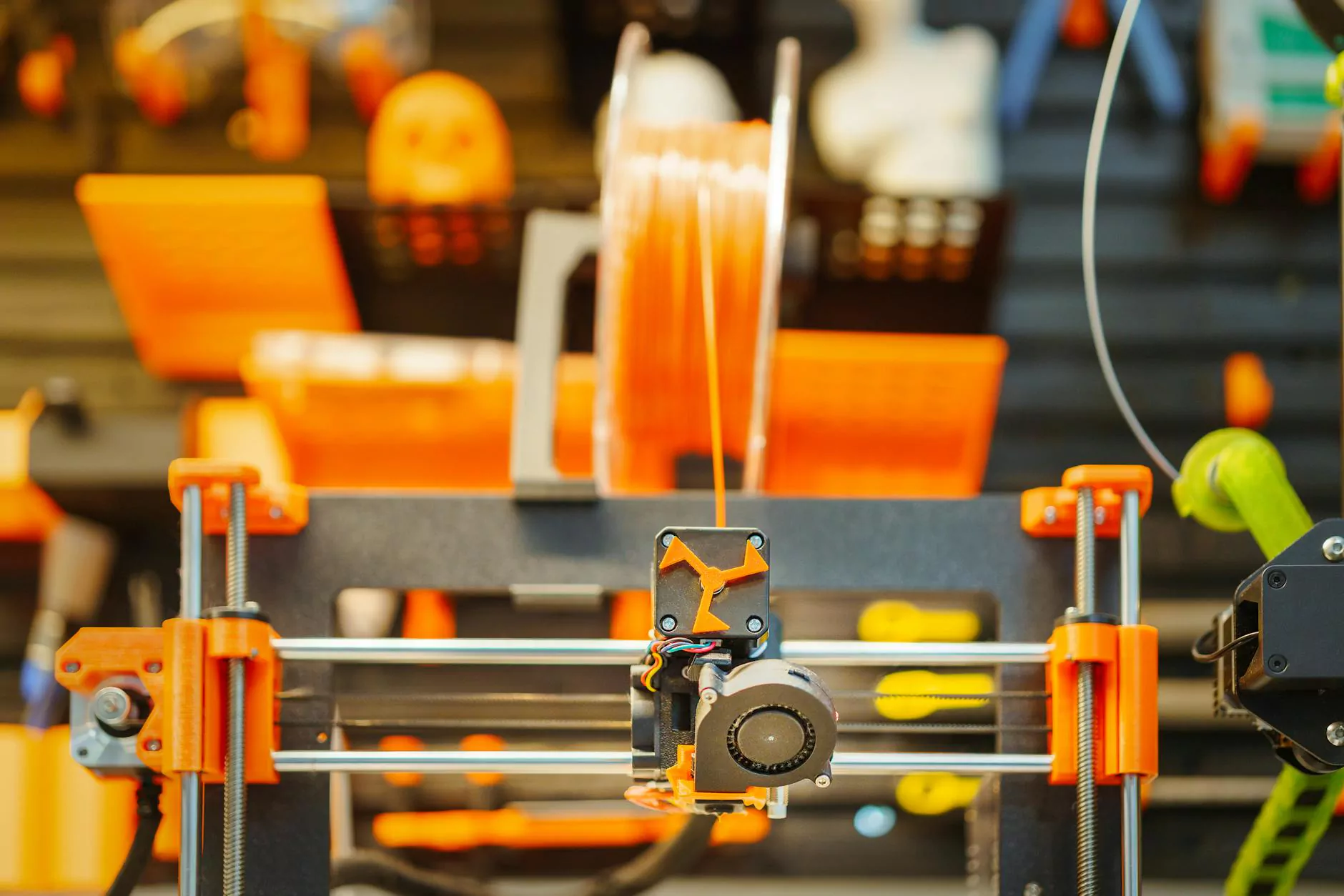

The Power of 3D Printing in Manufacturing Street Cleaning Trucks

3D printing, or additive manufacturing, enables the creation of complex parts and entire components with unparalleled precision and speed. Its applications within the realm of street cleaning trucks are vast, ranging from rapid prototyping and custom parts production to full-scale component manufacturing.

Key benefits include:

- Rapid prototyping: Shortening development cycles, allowing companies to test new ideas quickly and economically.

- Customization: Designing tailored components to meet specific urban sanitation needs.

- Cost reduction: Minimizing material waste and reducing manufacturing costs, especially for small batch productions.

- Design flexibility: Creating complex geometries that are difficult or impossible with traditional manufacturing methods.

- Sustainable production: Using eco-friendly materials and enabling on-demand manufacturing to reduce inventory and waste.

In the context of street cleaning trucks, 3D printing facilitates the production of specialized nozzles, spray systems, mounting brackets, and even entire body panels, significantly enhancing maintenance and operational flexibility.

Enhancing Performance and Sustainability of Street Cleaning Trucks through 3D Printing

The integration of 3D printing in manufacturing not only improves performance but also promotes environmental sustainability—an essential aspect for modern urban maintenance equipment. Here’s how this technology is transforming street cleaning trucks:

Optimized Design and Lightweight Components

Using 3D printing, engineers can design components that are lighter and stronger, contributing to reduced fuel consumption and emissions. Lightweight materials like advanced polymers and composites can be precisely shaped to withstand harsh operational conditions while minimizing weight.

Customized Cleaning Attachments and Accessories

Custom tools like brushes, nozzles, and spray systems can be rapidly produced to adapt to specific urban environments. This flexibility allows operators to optimize cleaning patterns, improve efficiency, and reduce water and chemical usage.

Rapid Maintenance and Repair

On-demand 3D printing enables quick replacement of broken or worn parts on the field, significantly reducing downtime and maintenance costs. This agility ensures continuous operation and better service delivery.

Innovative Applications of 3D Printing in ceksansweepers.com and Beyond

Leading industry players are harnessing 3D printing to push the boundaries of street cleaning truck design. For example:

- Prototype Development: Rapidly bringing to life new features, such as automated water sprays or sensor integrations, enabling a faster route to market.

- Custom Parts Manufacturing: Creating bespoke, durable components tailored to specific city requirements, improving overall efficiency.

- Eco-Friendly Materials: Utilizing biodegradable or recyclable materials in 3D printing processes to reduce the environmental footprint.

- Complex Geometries for Improved Efficiency: Designing aerodynamic and hydrodynamic parts that cut down on drag and water usage, promoting sustainability.

This innovative approach not only brings about functional benefits but also aligns with the corporate social responsibility goals of urban municipalities and eco-conscious businesses.

The Future of Business in 3D Printing and Urban Sanitation

As 3D printing technology continues to advance, its influence in developing smarter, more sustainable street cleaning solutions will accelerate. Market forecasts predict a significant increase in the adoption of additive manufacturing for municipal equipment, driven by economic, environmental, and operational advantages.

Furthermore, companies like ceksansweepers.com are positioned at the forefront of this transformation, integrating cutting-edge 3D printing techniques into their manufacturing processes to deliver innovative street cleaning trucks that meet modern urban demands.

Key Trends to Watch

- Integration of IoT and Smart Technologies: Embedding sensors and connectivity in 3D-printed components for real-time monitoring and control.

- Sustainable Manufacturing: Emphasizing biodegradable materials and energy-efficient 3D printing processes.

- Customization at Scale: Enabling local manufacturing hubs to produce tailored components quickly and cost-effectively.

- Enhanced Durability and Wear-Resistance: Developing new material composites suitable for harsh operational environments.

Why Businesses Should Invest in 3D Printing for Urban Sanitation Equipment

Investment in 3D printing offers substantial competitive advantages for companies operating in urban sanitation and public service domains:

- Innovation Leadership: Staying ahead in a competitive market by adopting cutting-edge manufacturing techniques.

- Cost Efficiency: Reducing manufacturing and maintenance costs through rapid prototyping and on-demand production.

- Operational Agility: Quickly adapting to evolving city regulations, environmental standards, and operational needs.

- Sustainability Goals: Supporting eco-friendly initiatives that appeal to environmentally conscious customers and municipalities.

- Enhanced Customer Satisfaction: Delivering customized, efficient, and sustainable products that meet diverse urban sanitation challenges.

As urban areas become increasingly concerned with environmental impact and operational resilience, businesses embracing 3D printing are positioned to excel in urban sanitation markets globally.

Conclusion: Embracing Innovation for a Cleaner, Greener Future

In conclusion, the integration of 3D printing technology into the manufacturing and design of street cleaning trucks marks a pivotal shift toward smarter, more efficient, and sustainable urban sanitation solutions. Companies like ceksansweepers.com exemplify how innovation and technology converge to meet the complex challenges of modern cities. Embracing these advancements not only enhances operational capabilities but also aligns with broader goals of environmental stewardship and quality of urban life.

As the industry continues to evolve, the adoption of 3D printing will undoubtedly play a central role in redefining what is possible in urban sanitation and infrastructure maintenance, paving the way for a cleaner, healthier, and more sustainable future for cities worldwide.