China Rapid Prototype Service: Revolutionizing Modern Manufacturing

What is Rapid Prototyping?

Rapid Prototyping is a crucial manufacturing technique that allows for the quick fabrication of a physical part or assembly using 3D computer-aided design (CAD). This process involves various technologies that can convert digital files directly into tangible models. The significance of rapid prototyping lies in its ability to accelerate the development cycle of products, providing manufacturers with the flexibility to test, iterate, and refine designs swiftly.

The Rise of China's Rapid Prototype Service

In recent years, the China rapid prototype service sector has gained remarkable traction on a global scale. Manufacturers across various industries have turned to China for its unparalleled service quality, affordability, and efficiency. China's vast resources and skilled workforce make it a prime location for companies looking to implement effective prototyping solutions. The following factors illustrate why China's rapid prototyping services are the preferred choice for businesses worldwide:

- Cost-Effectiveness: The labor and material costs in China are comparatively lower, making prototyping services much more affordable.

- Speed: Professional service providers guarantee quick turnaround times, often allowing clients to have their prototypes within days.

- Expertise: With a growing number of skilled technicians and engineers, China’s workforce is exceptionally well-trained in advanced manufacturing technologies.

- Technology Adoption: Chinese companies are at the forefront of adopting the latest technologies in prototyping, including 3D printing, CNC machining, and more.

- Scalability: Businesses can easily increase the scale of production according to their needs, thanks to flexible manufacturing capabilities.

The Key Technologies in Rapid Prototyping

Understanding the technologies that underpin the China rapid prototype service is vital for businesses seeking to leverage these advancements. Here are the most common methods used:

1. 3D Printing

3D printing, or additive manufacturing, has transformed prototyping. This method creates three-dimensional objects by layering materials based on digital models. It supports a wide range of materials, including plastics, metals, and composites, opening avenues for highly complex designs that traditional manufacturing cannot achieve.

2. CNC Machining

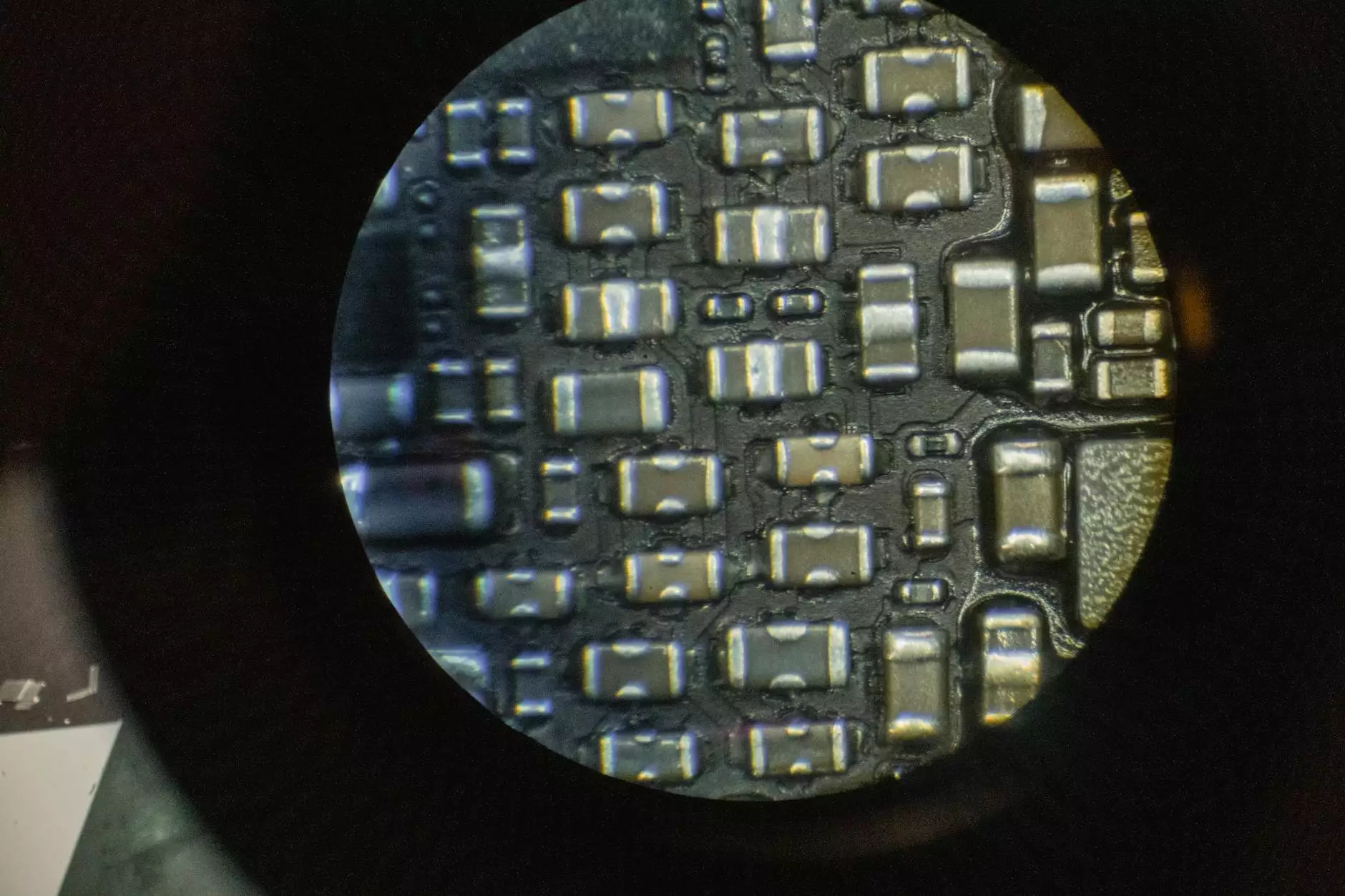

CNC (Computer Numerical Control) Machining is a subtractive manufacturing process that uses pre-set computer programs to dictate the movements of machinery. This method is ideal for creating precision parts from various materials, providing a high level of accuracy and repeatability.

3. Injection Molding

Injection molding is a widely used manufacturing process for creating parts by injecting molten material into a mold. This method is particularly effective for mass production and can be integrated into prototyping to validate designs before full-scale production.

4. Sheet Metal Fabrication

Sheet metal fabrication involves bending, cutting, and assembling thin sheets of metal to create functional prototypes. It is extensively used in industries such as automotive, aerospace, and consumer electronics.

Benefits of Choosing a China Rapid Prototype Service

Engaging a China rapid prototype service provider not only accelerates product development but also offers several benefits that can significantly enhance your manufacturing process:

- Prototype Testing: Rapid prototyping allows businesses to identify design flaws and operational issues early in the development cycle.

- Design Flexibility: Designers can easily make adjustments based on feedback from testing phases, significantly improving the final product.

- Market Readiness: Companies can bring products to market faster, ensuring they stay competitive in fast-paced industries.

- Enhanced Collaboration: Prototyping encourages better communication between the design and production teams, leading to improved outcomes.

- Environmental Considerations: Many rapid prototyping services in China emphasize sustainable practices, utilizing recycled materials and eco-friendly processes.

Choosing the Right Service Provider

When selecting a China rapid prototype service provider, it is essential to evaluate their capabilities, quality of work, and reputation. Here are some key factors to consider:

1. Experience and Expertise

Look for a provider with substantial experience in rapid prototyping. This includes a track record of successful projects across various industries. Expertise in multiple prototyping technologies is also a plus.

2. Quality Assurance

A reliable service provider should have stringent quality control measures in place. Verify their certifications and processes to ensure they meet international standards.

3. Customer Reviews

Research customer testimonials and case studies. Positive feedback from previous clients can provide insight into the provider's reliability and service levels.

4. Communication and Support

Effective communication is crucial in prototyping. Ensure the service provider is responsive and open to collaboration throughout the project.

Case Studies of Successful Rapid Prototyping in China

Several companies have leveraged China rapid prototype services to gain a competitive edge:

Case Study 1: Automotive Innovations

A leading automotive manufacturer partnered with a Chinese rapid prototyping service to develop new components for their electric vehicle models. By utilizing 3D printing and CNC machining, they succeeded in reducing development time by over 30%, allowing them to launch their new model ahead of competitors.

Case Study 2: Consumer Electronics

In the consumer electronics sector, a prominent tech company collaborated with a rapid prototyping firm in China to refine their product design phase. Through iterative prototyping, they identified key improvements, resulting in a more user-friendly device that significantly increased market appeal.

Future Trends in China’s Rapid Prototyping Sector

The future of the China rapid prototype service market looks promising, with several trends shaping its evolution:

- Increased Automation: The rise of automation technologies will streamline prototyping processes, improving efficiency and reducing costs.

- Advancements in Materials: Continuous research in new materials, including bio-degradable plastics and advanced composites, will expand the possibilities in prototyping.

- Integration with AI: Artificial Intelligence (AI) will enhance design processes, enabling smarter, data-driven decisions.

- Sustainability Initiatives: A growing emphasis on sustainability will drive the adoption of eco-friendly practices in prototyping.

Conclusion

In the era of rapid technological advancement, businesses cannot afford to lag in their product development cycles. The China rapid prototype service stands as a beacon of innovation and efficiency, offering companies the tools needed to bring ideas to fruition rapidly and effectively. By leveraging China's expertise in advanced prototyping technologies, businesses can enhance their competitive edge and respond swiftly to market demands. Whether you’re in the automotive, consumer electronics, or any other industry, integrating rapid prototyping into your product development strategy is essential for success in today's fast-paced market.